The first Swiss hydrogen filling station for buses

- Europe

- Clean mobility

- Mobility

- Renewable hydrogen

- Usage

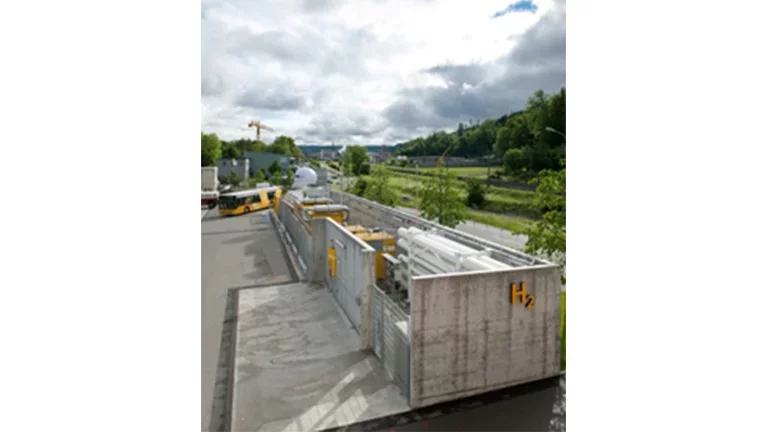

May 22nd, the latest generation hydrogen refuelling station, provided by Carbagas, the Swiss subsidiary of Air Liquide, and developed by Air Liquide teams responsible for designing and manufacturing of hydrogen stations has opened in Brugg.

Within the European project CHIC (Clean Hydrogen in European Cities), PostBus has invested in 5 fuel cell buses. Those vehicles convert the tanked hydrogen fuel into electrical energy driving energy. In addition to being silent, the fuel cell technology allows the bus to be neutral in CO2 emissions, and PostBus expects to save at least 2000 tons of CO2 during the 5 years trial phase.

Since hydrogen is produced on site, the station includes an electrolyser which turns water and electricity into hydrogen. When electricity is passed through water, the water splits into hydrogen and oxygen. 100% of the electricity used to produce hydrogen is obtained from renewable energies such as solar and wind, hydro and biomass energy. The hydrogen station consists of two high pressure compressors that compress hydrogen to 410 bars (while buses are filled to 350 bars) which is then stored in high pressure tanks. Used in a fuel cell, placed on the roof of the bus, the hydrogen combines with oxygen in the air to produce electricity while discharging nothing more than water.

The planet is now facing a dual challenge, regarding the environment as well as energy. In this context, access to sustainable mobility is a major issue if greenhouse gases and pollution in cities are to be reduced and our dependence on oil-based fuels is to be cut. Hydrogen, used as an energy vector, is one of the solutions that can be used in the short-term to face up to these challenges.

To go further :

www.carbagas.ch

Video - "The fuel cell postbus

|

Station features: Maximum production day on site: 2500 nm3 (standard cubic meters) |